Asphalt concrete heat preservation truck GXMER-BY20000

Product scope of application:

Asphalt concrete heat preservation truck is a professional asphalt road construction equipment, which has the function of heating and heat preservation transportation of asphalt mixture, and is widely used in heat preservation transportation of asphalt mixture paved on pavement.

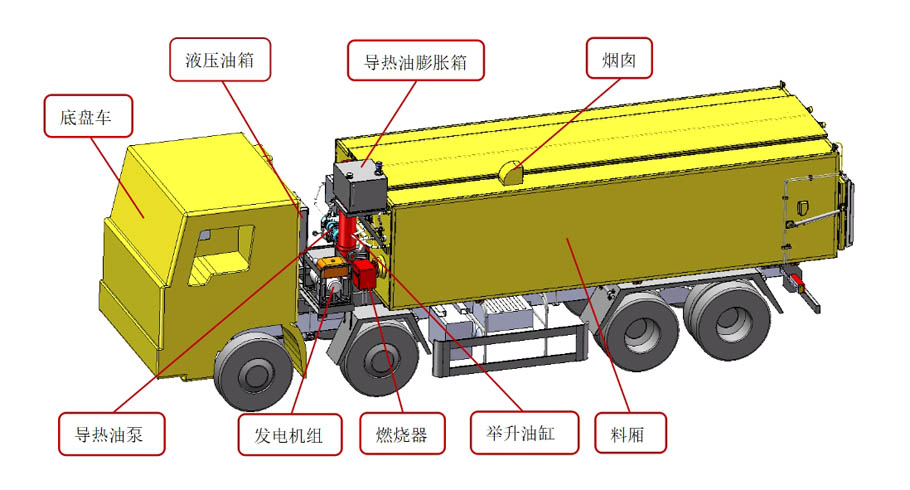

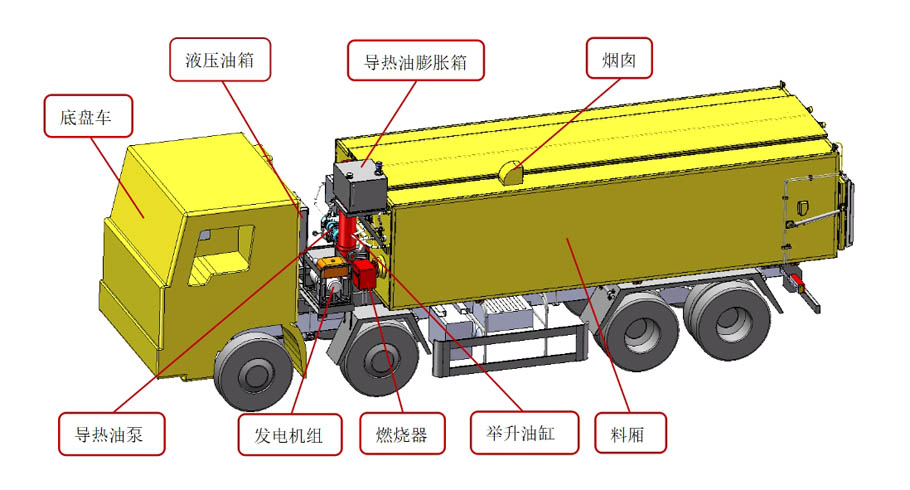

The equipment is mainly composed of traveling system (chassis car), self-unloading insulating material compartment, heat conducting oil heating and circulating system, lifting mechanism, auxiliary frame assembly, electrical control system, hydraulic system, generator system, etc.

Product working principle:

Asphalt concrete heat preservation transporter adopts lifting type fully sealed heat preservation carriage storage mode, dump type discharging system, and heating carriage adopts heat conducting oil circulation heating mode, avoiding direct heating of asphalt material and leading to oxidation scaling and aging denaturation.

Product structural Introduction:

Product performance advantages:

●High performance chassis

It adopts the famous domestic brand Dongfeng Tianlong Guo Six Chassis Vehicle, which has strong power. Its main function is to load the working device and provide working power. It can adapt to various application occasions.

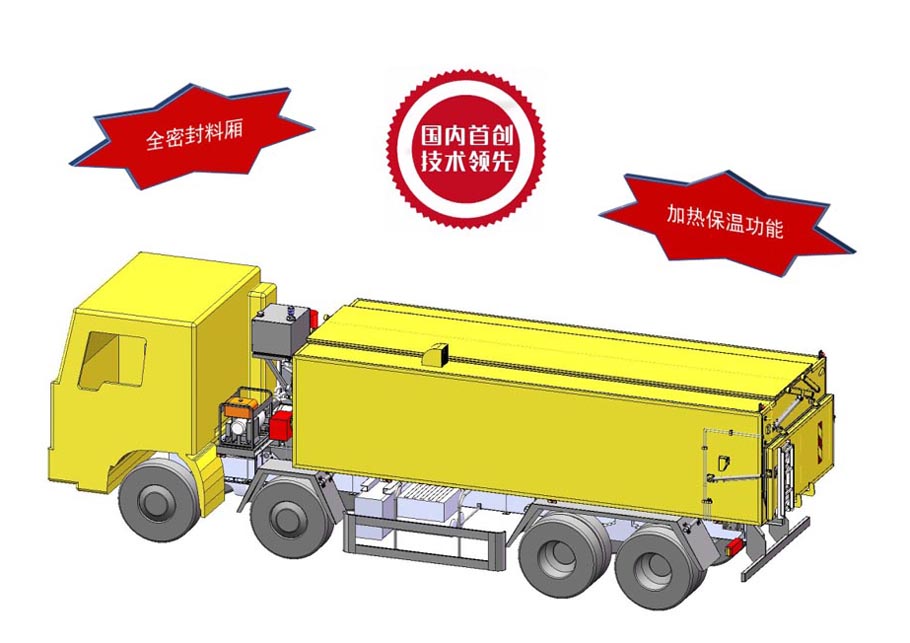

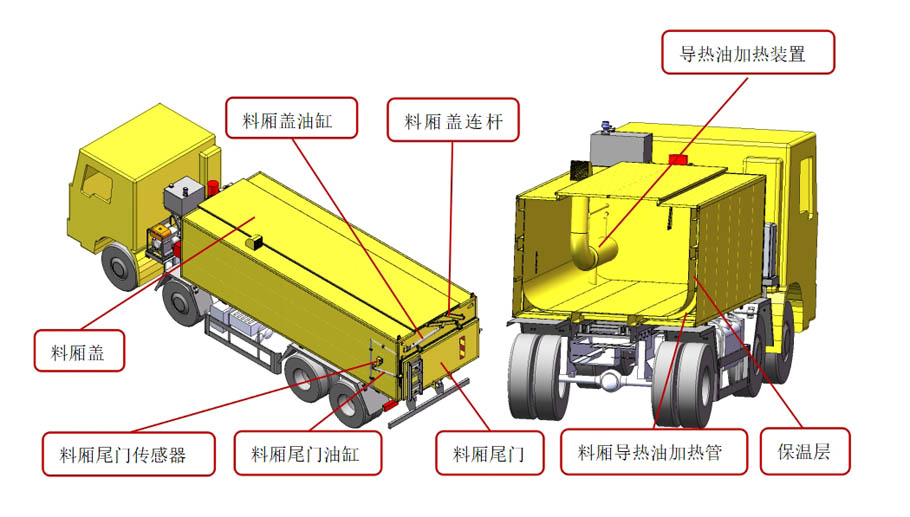

●Structure of material compartment

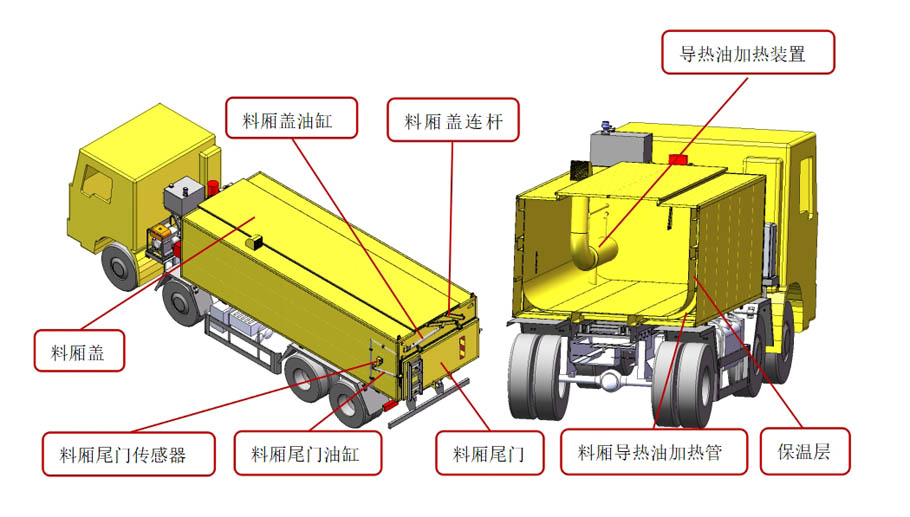

The material compartment is fully sealed. The bottom plate, side plate and front and rear plates are made of high strength steel. The bottom is designed to be arc-shaped, wear-resistant and effectively avoid material accumulation. The material compartment cover adopts a four-bar structure and is driven by a hydraulic cylinder. When closed, it can form a seal with the material compartment body. When the material compartment cover is opened, it is vertically located on the right side of the material compartment, horizontally and vertically. Small size, easy to load asphalt mixture, the tail door of the material compartment is driven by hydraulic cylinder, and equipped with cylinder claw hook, which ensures the closure of the tail door of the material compartment is tight. The whole material compartment is wrapped with 30 mm thick aluminum silicate material, which can withstand 1250 C high temperature, as a heat insulation layer, which can prevent heat loss to the greatest extent.

●Reliable heating and insulation

The average transportation distance from asphalt mixing station to construction site is within 20-30 km, but the farthest distance may be more than 50 km. There is a phenomenon of long-distance transportation in an engineering project. After 2.5 hours of transportation, the temperature of asphalt mixture inside the carriage decreases by about 10 C, and the top of the carriage decreases. The temperature of asphalt mixture decreases about 30 C in the range of 3cm at the top, and loses quickly in the range of 3cm at the edge, and decreases about 60 C at the bottom. The heating and insulation system equipped with this equipment can ensure that the temperature of asphalt mixture decreases within 10 C during transportation.

●Heat conducting oil heating system

The interior of the material compartment is designed with heat-conducting oil heating device. The special structure design is adopted on both sides and bottom. The heat-conducting oil after heating can be divided into two routes for cyclic heating. The whole material compartment, material compartment cover and material compartment tail door are covered with insulating cotton for thermal insulation, which can ensure the temperature of asphalt mixture during construction, improve construction quality and avoid asphalt mixing. The phenomenon of waste caused by the temperature drop of mixture during long distance transportation or transportation in rainy days.

●Discharging system

The front-roof dump unloading and the well-known brand Holland Haiwo are adopted in the lifting system. The lifting angle is 48 + 2 degrees, which can effectively and quickly remove the asphalt mixture, improve the construction efficiency and reduce the labor intensity.

●Independent power system

It is equipped with independent generating units to provide power for heat conducting oil pumps and burners. It can also be heated and insulated when the chassis car is out of operation.

●Control system

It is equipped with temperature sensor of heat conducting oil inside and outside of material compartment, switch of material compartment cover, material compartment tail door, heat conducting oil pump and burner etc. integrated in operation electric box, installed in cab, heat conducting oil heating temperature can be set, burner automatically extinguishes after reaching the set temperature, and has low liquid level alarm. When the heat conducting oil level is low, The burner stops working to ensure the safe operation of the heating system, the sensor with the material compartment falling in place to ensure the safety of the whole vehicle transportation, and the sensor with the opening angle of the rear door of the material compartment to ensure the safety of the material compartment lifting.

Product parameters:

Bunker volume | 20m3 |

Internal dimensions of hopper | 6410×2170×1420mm (length * width * height) |

Hoisting angle of hopper | 48±2° |

Chassis | DFH3310A18 |

Emission standard | GB3847-2005,GB17691-2018 Country Ⅵ |

Maximum total weight | 31000kg |

Vehicle size | 10280×2550×3510mm (length * width * height) |

Product Function System:

Alternator |

Brand | Chang Chai |

Fuel tank volume | 12L |

Output power | 6.5kW |

Output voltage | 400/230V |

Hydraulic system |

Hydraulic oil specification | 46# |

Fuel tank volume | 132L |

Control mode | Electronic control |

Heat Conducting Oil Heating System |

Thermal conductive oil Specifications | 320# |

Volume of heat conducting oil | 720L |

Heat conducting oil pump |

flow | 6 m3/h |

Power | 1.5kW |

Burner |

Brand | Riyal Road |

Quantity of heat | 200,000 cards |

Lifting system |

Brand | Netherlands Haywar |

Model | R-Line 68.84 |

You choose not only reliable products,There are also high-quality services!